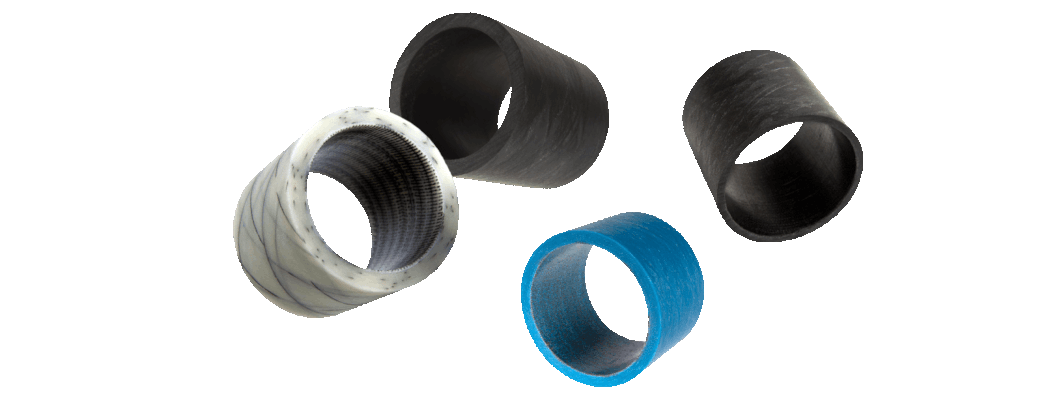

Polygon’s bearings feature three distinct components:

- Continuous glass fibers

- Polymer resin

- TFE fabric liners

The fiberglass filament and epoxy resin combined form a very high strength backing. This precise filament wound fiberglass structure allows for thin walled bushings (1/16″ to 1/8″), reducing the size and weight of assemblies.

Greaseless Bearings

PTFE liners provide permanent lubrication unlike sintered metals which lose oils over time.

Secondary lubrication is not necessary during start-up due to PTFE film transfer to the shaft.

Long Life Cycle

Testing shows wear under 0.006″ after 1.6 million cycles, made possible by a woven structure of

PTFE super-filaments with tensile strengths twenty times greater than PTFE resins. As a result,

the bushing resists cold flow under high loads.

Handles Industrial-level Strain

PolyLube composite bearings support a load of up to 30,000 PSI while handling high radial and

axial stresses. They resist high shock loading and impact fatigue due to their unique high strength

continuous filament wound fiberglass backing. PolyLube bearings are ideal for high load

operation in rotational and linear movements as well as in oscillation.

Exceptional Dimensional Stability

They exhibit high performance predictability over wide temperature ranges, ±325°F for all

configurations, and up to 475°F for high temperature bearings. From desert heat to bitter cold

environments, composite bearings will not pinch the pin or lose the interference fit with the bore.

The coefficient of thermal expansion for the PolyLube bearing is approximately 4.8×10 –

6 °F. Learn more

Singular Focus

Composite products are not our sideline; it is our profession. We engineer, design, manufacture,

and test composite bearings and wear materials. We offer high temperature, high impact, food

grade, insulating, corrosion resistant and numerous other specialty composite bearings.