TAILORED SOLUTIONS

CUSTOMIZE POLYGON

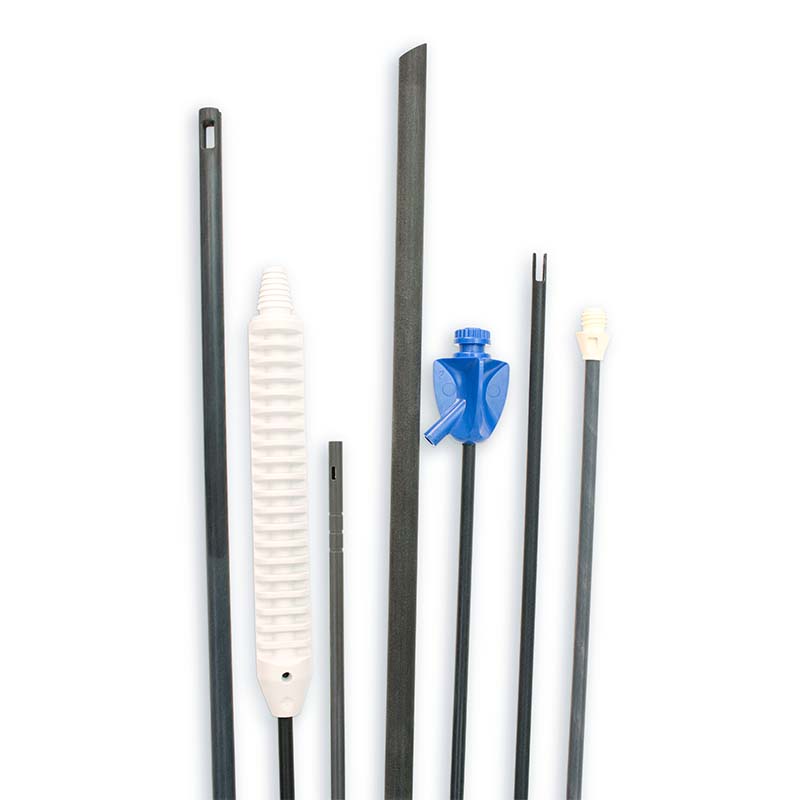

MEDICAL TUBING

Completely custom to your application

Polygon medical tubing is a customizable mixture of resin and fiberglass that’s wound, pultruded, or braided into a strong, thin form that’s designed to your exact specifications for minimally invasive surgical procedures in virtually every niche.

TAILOR TO YOUR NEEDS

MATERIAL MIX

Polygon composites are made using a mixture of fiberglass and resin that’s customizable for your application.

CIRCUMFERENTIALLY WOUND

The combination of fibers that are oriented both helically and axially provides high strength with excellent elasticity.

BRAIDED

Fibers are interlocked into a circular shape that provides excellent strength in especially thin-walled tubes.

UNIDIRECTIONAL FIBERS

When rigidity is most important, choose unidirectional continuous fiber reinforced tubing for superior stiffness.

LUMENS

Multiple chambers (aka “lumens”) can be housed within one tube, safely isolated from each other.

INNER/OUTER DIAMETER

You can control both the outer and inner shape and diameter of each Polygon composite tube.

READY TO START CUSTOMIZING?

Developing unique composite fiber architectures and hybrids for distinct industries and applications is our specialty. Our composite experts partner with your design engineers to create the very best solution for your exact situation.