CONSTRUCTION

DESIGN BETTER PERFORMANCE INTO YOUR NEXT

PROJECT

POLYGON’S CONSTRUCTION EQUIPMENT BEARINGS HELP OPERATORS STAY PRODUCTIVE WHILE REDUCING MAINTENANCE COSTS.

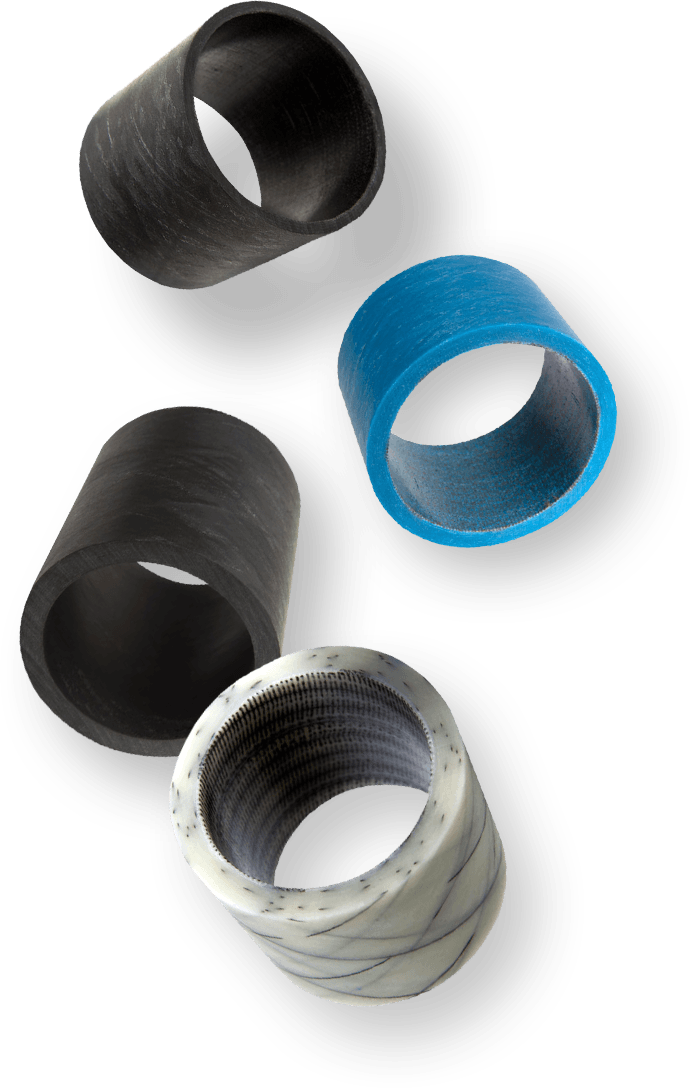

Polygon bearings are engineered to be self-lubricating and maintenance-free, providing an ideal solution for many construction and heavy equipment applications. Manufacturers of construction and other off-highway equipment trust Polygon composite bearings to deliver excellent load capacities, low friction, resistance to corrosion and other benefits. Leading equipment manufacturers and their Tier-1 suppliers rely on Polygon’s bearing assemblies to deliver the performance demanded by the construction industry.

POTENTIAL APPLICATIONS

- Excavators

- Mini & micro excavators

- Bulldozers

- Backhoes

- Skid steers

- Wheel loaders

- Mining equipment

- Articulating joints

- Cylinder base and rod ends

- Cylinder movement pivot points

WHEN TO DESIGN IN POLYGON COMPOSITE BEARINGS

- Self-lubrication is required

- Bearing neglect could lead to product liability claims or premature failure

- Maintenance costs need to be closely monitored

- Stick-slip conditions exist

- High load capacities are needed

- Resistance to chemical, galvanic or fretting-related corrosion is a problem

- Galling and scoring need to be minimized

- Electrical insulation is required